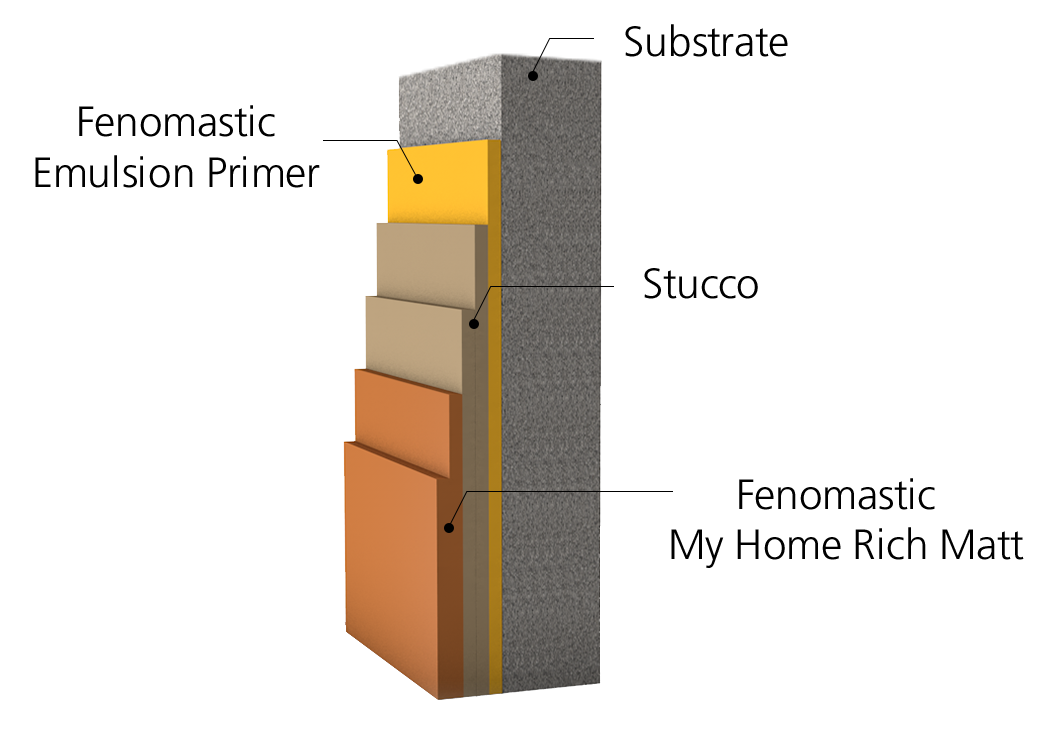

Interior Paint System

Surface preparation has an important role in the performance of all paint systems.

The surface must be sound, clean, dry and completely free from dust, oil, grease, chemicals, etc. All loose particles, sharp edges, nibs and other protrusions should be removed by abrading the surface with sand paper, scraper, rubbing stone, or a similar abrasive, followed by removal of the accumulated dust.

The first layer is a

primer

, the main task of which is to seal the substrate and provide required adhesion to the full system with the substrate. This is normally applied with a cotton roller.

The second and third layers will be a putty/stucco, which is applied to provide smoothness to the substrate and hide minor substrate imperfections. This is normally applied with a spatula and putty knife.

The fourth and fifth layers will be the

topcoat

. This provides all the major features/properties of the system like colour, washability, hiding, light reflective properties, crack bridging ability, antifungal/antibacterial properties etc. This is normally applied with a cotton roller.

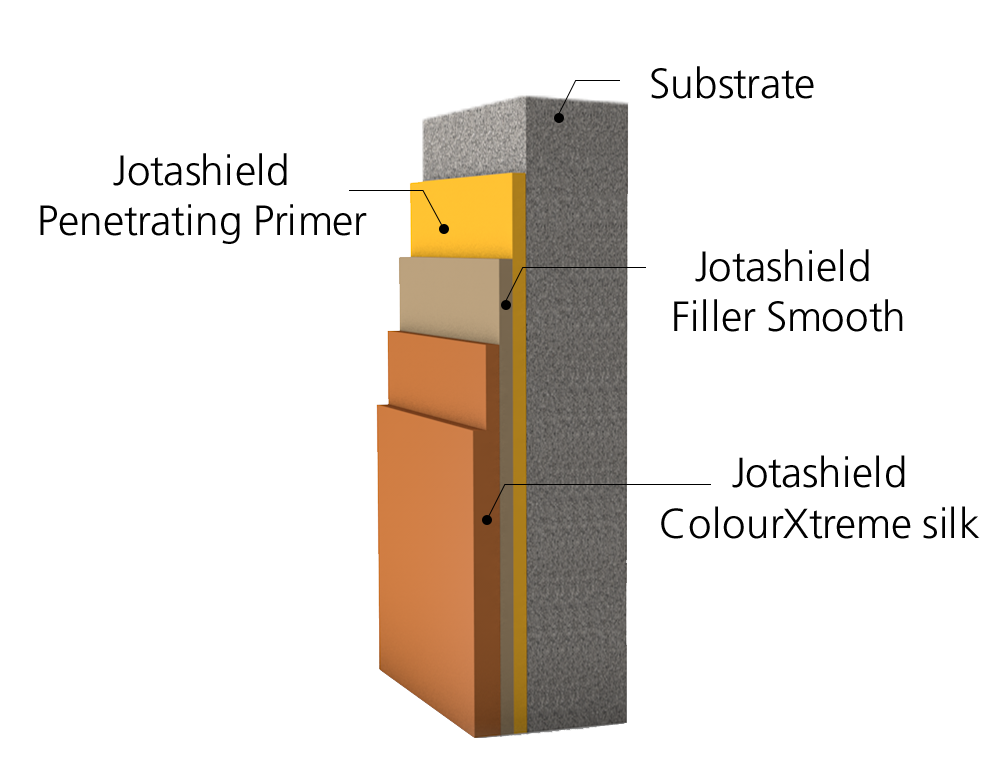

External Smooth Paint system

This system normally comprises of 4 different layers. In cases where substrate has more imperfections, 5 layer system can be recommended.

Surface preparation has an important role in the performance of all paint systems.

The surface must be sound, clean, dry and completely free from dust, oil, grease, chemicals, etc. All loose particles, sharp edges, nibs and other protrusions should be removed by abrading the surface with sand paper, scraper, rubbing stone, or a similar abrasive, followed by removal of the accumulated dust.

The first layer is a

primer

, the main task of which is to seal the substrate and provide required adhesion to the full system with the substrate. It is normally applied with a cotton roller

The second (also an extra layer if required) is an external grade

filler/putty

which has the ability to withstand external weather conditions like high temperature, humidity etc. This filler is applied to provide smoothness to the substrate and hide minor substrate imperfections. This layer will also act as excellent base for subsequent coats, and is normally applied with a trowel, spatula and putty knife.

The third and fourth layers will be the

topcoat

. This will provide all the major features/properties of the system like colour, hiding, light reflective properties, crack bridging ability, UV resistance, moisture/water resistance, anticarbonation property, thermal reflective property etc. These are normally applied with cotton roller

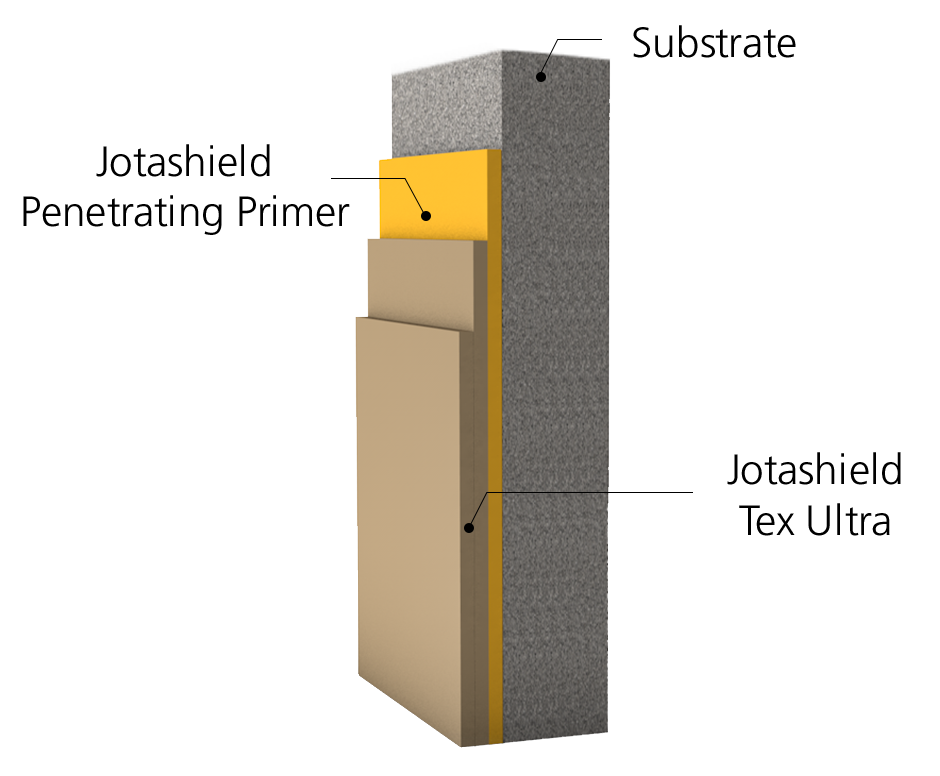

External Textured Paint system

This system normally comprises of 4 different layers.

Surface preparation has an important role in the performance of all paint systems.

The surface must be sound, clean, dry and completely free from dust, oil, grease, chemicals, etc. All loose particles, sharp edges, nibs and other protrusions should be removed by abrading the surface with sand paper, scraper, rubbing stone, or a similar abrasive, followed by removal of the accumulated dust.

The first layer is a primer, the main task of which is to seal the substrate and provide required adhesion to the full system with the substrate. This is normally applied with a cotton roller

The second layer is an external grade texture layer which has the ability to withstand the external weather conditions like high temperature, humidity etc. This layer is applied to provide a textured appearance to the substrate, and reduce the impact of undulations and minor substrate imperfections. This is normally applied with a hopper gun.

The third and fourth layers will be the

topcoat

. This provides all the major features/properties of the system like colour, hiding, light reflective properties, crack bridging ability, UV resistance, moisture/water resistance and anticarbonation property. These are normally applied with a cotton roller.

External Textured Paint system with built in textures

This system normally comprises of 3 different layers.

Surface preparation has an important role in the performance of all paint systems.

The surface must be sound, clean, dry and completely free from dust, oil, grease, chemicals, etc. All loose particles, sharp edges, nibs and other protrusions should be removed by abrading the surface with sand paper, scraper, rubbing stone, or a similar abrasive, followed by removal of the accumulated dust.

The first layer is a

primer

, the main task of which is to seal the substrate and provide required adhesion to the full system with the substrate. It is normally applied with a cotton roller

The second and third layers will be the

topcoat

which have built-in textures within themselves, thereby eliminating the need for separate texture coat and topcoats. They provide all the major features/properties of the system like colour, texture, hiding, light reflective properties, crack bridging ability, UV resistance, moisture/water resistance, anticarbonation property etc.

These texture topcoats provide textured appearance to the substrate, and also reduce the impact of undulations and minor substrate imperfections.

These topcoats are applied with a honey comb/sponge roller.

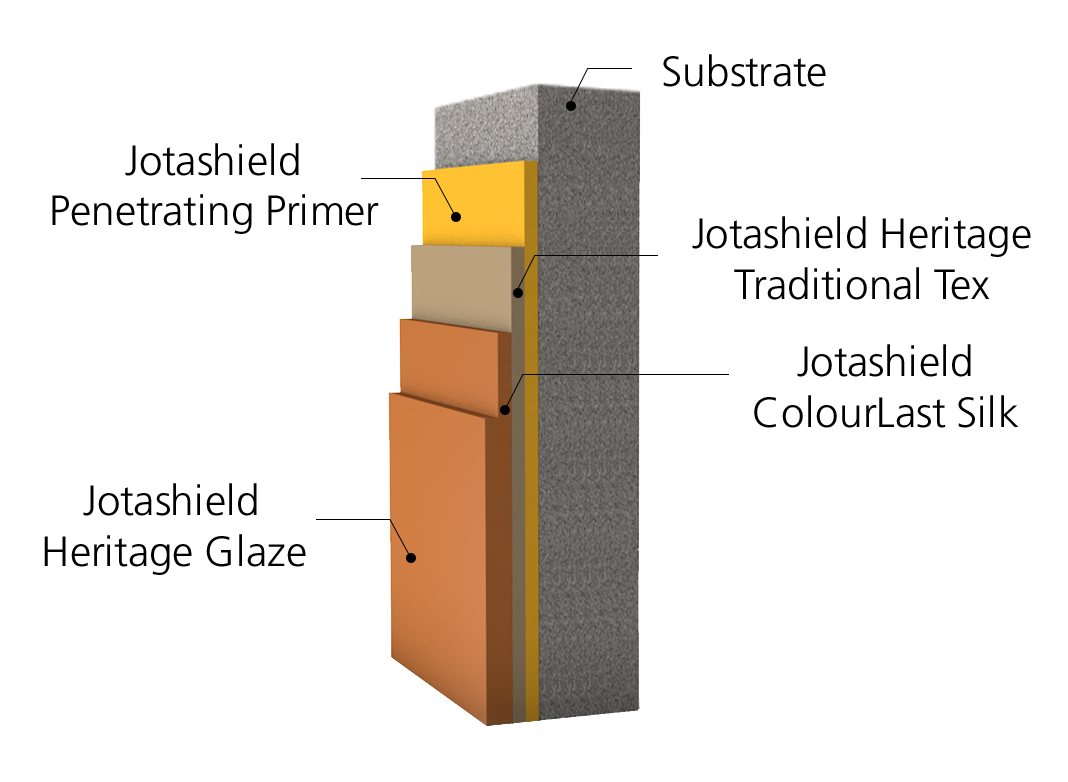

External Heritage Textured Paint system

This system normally comprises of 4 different layers. If more build up is required, an additional layer of heritage texture can be applied.

Surface preparation has an important role in the performance of all paint systems.

The surface must be sound, clean, dry and completely free from dust, oil, grease, chemicals, etc. All loose particles, sharp edges, nibs and other protrusions should be removed by abrading the surface with sand paper, scraper, rubbing stone, or a similar abrasive, followed by removal of the accumulated dust.

The first layer is a

primer

, the main task of which is to seal the substrate and provide required adhesion to the full system with the substrate. It is normally applied with a cotton roller.

The second layer is an external

texture coat

which gives an old/ancient look. These heritage finishes can withstand external weather conditions and also minimise the impact of undulations and minor substrate imperfections. These are normally applied with trowel and spatula.

The third layer is a

smooth topcoat

which, along with the heritage texture coat, provide all the major features/properties of the system like colour, hiding, crack bridging ability, UV resistance, moisture/water resistance and anticarbonation property. These are normally applied with a cotton roller.

The fourth layer is an external grade glaze with long open time, which allows this product to be applied in various designs and decorative patterns. If the smooth topcoats and glaze colours are selected accordingly, a dual-effect can also be provided to the entire system, which will further enhance the old/ancient look. It can be applied by various methods using a brush and roller.